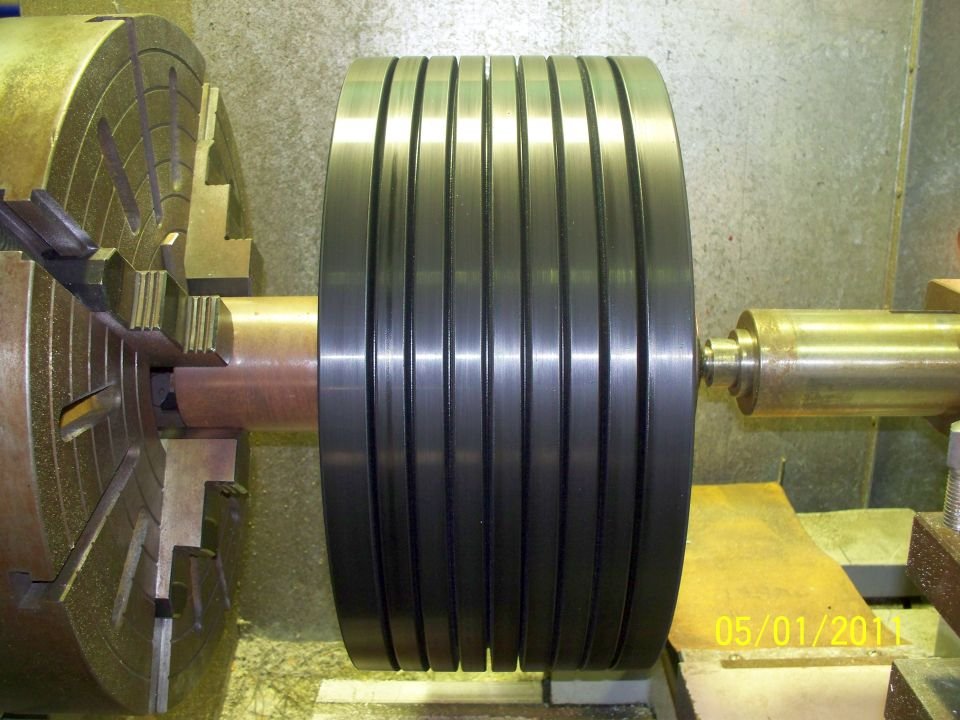

Polyurethane components for

Engineering

With personal supervision and in-house facilities, Polyurethane Processors have achieved an outstanding record in eliminating bond failures between polyurethane and metal substrates. This applies in particular to heavy duty solid tyred wheels and other critical components and custom made products.

-

Polyurethane is an ideal material for manufacturing wheels and rollers for various applications, including heavy machinery, conveyor systems, and automotive equipment. Its high load-bearing capacity, low coefficient of friction, and excellent wear resistance make it ideal for these applications.

-

Polyurethane bump stops are used to absorb shock and vibration due to its high resistance to deformation and durability.

-

Polyurethane vibration pads are used to reduce vibration and noise in various equipment and machinery.

-

Polyurethane has a low coefficient of friction and excellent wear resistance.

-

Polyurethane sealing rings are used in various hydraulic and pneumatic applications to prevent leakage and ensure a tight seal. Its excellent elasticity and resistance to wear and tear make it ideal for these applications.

-

Polyurethane covers and protectors are used to protect various equipment and machinery components from wear and tear, impact, and environmental factors. Its excellent resistance to abrasion and toughness make it ideal for these applications.

-

Polyurethane check valves are used in various drilling applications to prevent backflow and ensure a unidirectional flow of fluids. Its excellent resistance to wear and tear and low coefficient of friction make it ideal for these applications.

-

Polyurethane can be moulded into various custom shapes and sizes to meet specific application requirements, including bushings, seals, and other components. Its versatility and ability to provide unique mechanical properties make it ideal for these applications.